Equipment Introduction

The principle of dry ice deburring/cleaning is that dry ice particles are driven by compressed air and impact the surface to be deburred at high speed. The dry ice is crushed and sublimated in an instant. It absorbs a lot of heat. Due to the different thermal expansion coefficients of the burr and the substrate, the burr quickly cracks. The crushed dry ice particles enter the cracks, and due to the vaporization of the dry ice, its volume expands nearly 800 times in an instant. In this way, a "micro bomb" is created at the impact point,and the burr is quickly peeled off, achieving the best cleaning effect.

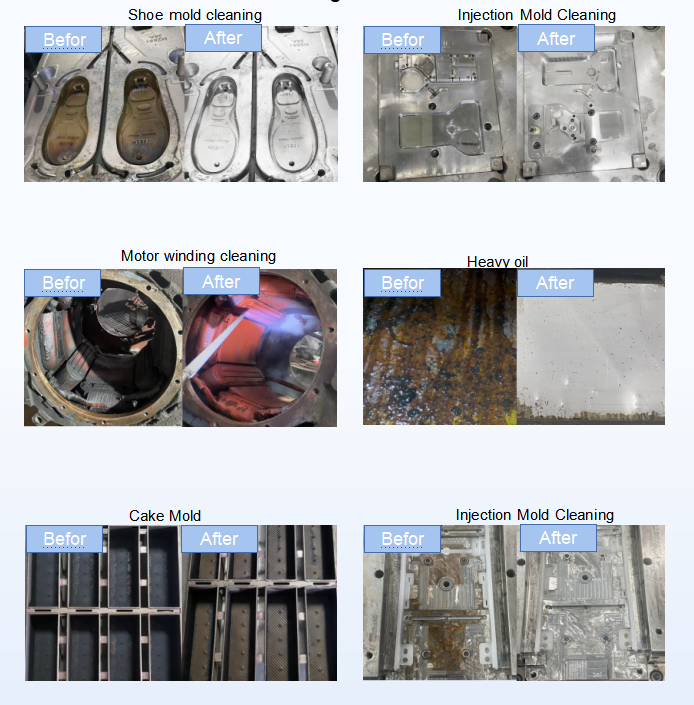

Main applications

1. Widely applicable for deburring in the 3C industry and the mold industry;

2. Gas consumption: 0.8-4.0m ³/min.

3. Gas supply pressure: 0.1-0.8Mpa

4. Adjustable ice feeding speed: 0-1.2 lbs/min (0.1-0.55KG/min)

5. Hopper capacity: 10Kg

6. Suitable for dry ice: 120 * 120 * 250mm (about 5KG)/150 * 150 * 300mm (about 10KG), power: 0.28KW

Technical performance

Other information

| Power | 0.36KW |

|---|---|

| Air consumption | 28-141CFM (0.8-4.0m³min) |

| Air supply pressure | 0.1-0.8Mpa (1-8bar Adjustable) |

| Ice delivery speed | 0-1.2 lbs/min (0-0.55Kg/min) Adjustable |

| Hopper capacity | Max. 22lbs(Max. 10Kg) |

| Protection level | IP52 |

| weight | 121lbs(55Kg) |

| Dry ice state | 120*120*250mm(约5KG)/150*150*300mm(约10KG) |

| Drive method | Direct link(Dual motors drive the cutter and rollers independently) |

| Dimension | (L)640x(W)400x(H)580mm |

whatsapp

whatsapp Email

Email

WhatsApp

WhatsApp

location

location