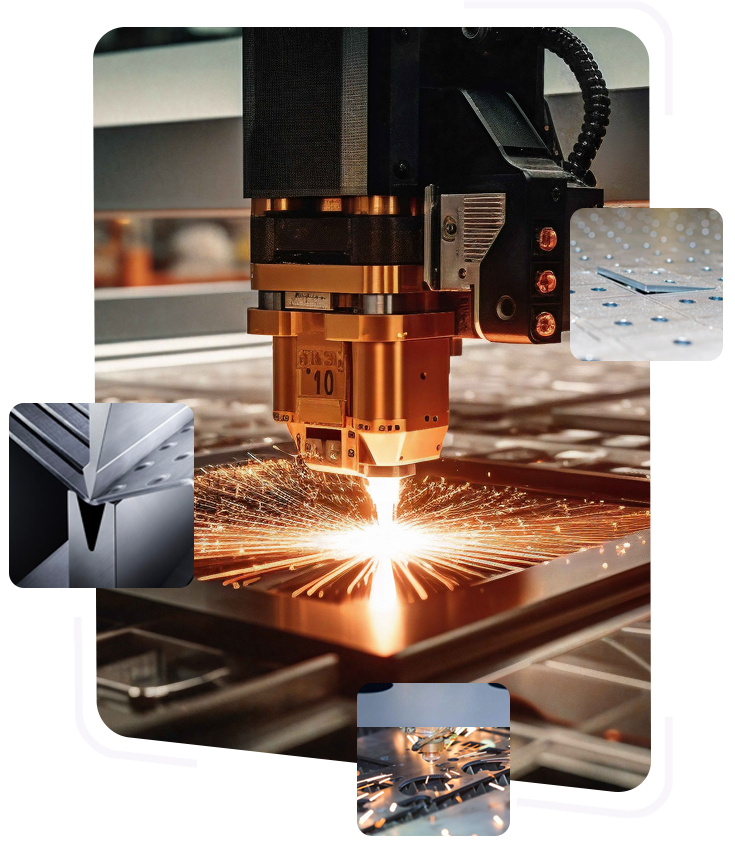

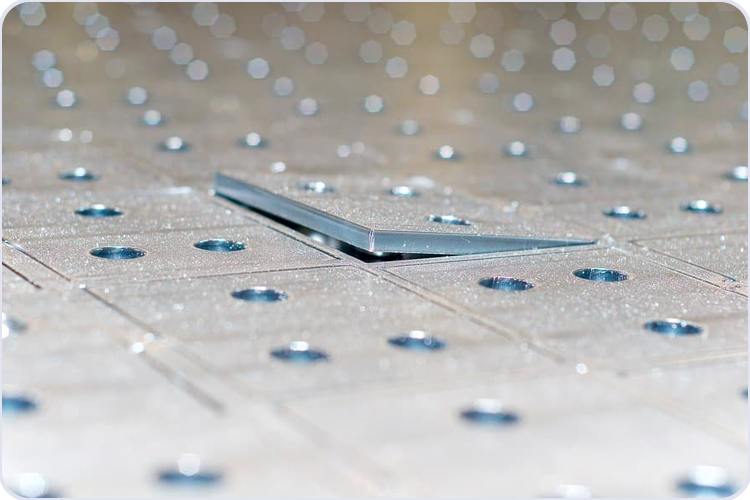

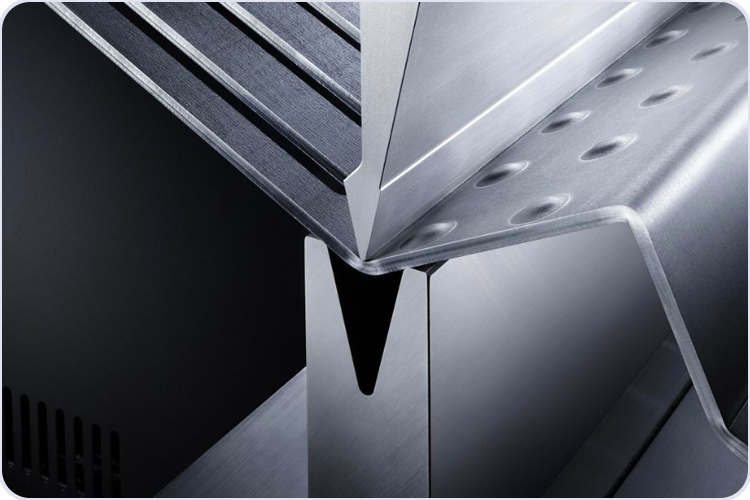

Jiacui provides metal cutting, riveting, welding, bending and other services to quickly process sheet metal parts for you. Large scale automated cutting equipment can ensure high-precision and high-quality requirements for components, and can also customize surface treatments such as spraying, electroplating, oxidation, etc.

| Material Classification | Specific material name | Main features | Applicable fields |

|---|---|---|---|

| Aluminum alloy | Aluminum Alloy | Lightweight, good strength, good thermal conductivity, easy to process | Vehicle shell, aerospace, electronic product shell |

| Steel | Cold Rolled Steel | High strength, good rigidity, high plasticity, easy to form | Automotive parts, electrical appliances, furniture, mechanical parts |

| Hot Rolled Steel | High strength, good toughness, low cost, weldable | Structural components, mechanical parts, ship parts | |

| Stainless steel | Stainless Steel | Corrosion resistant, high-strength, high-temperature anti-oxidation, easy to clean | Kitchenware, electrical appliances, medical equipment, chemical equipment |

| Galvanized steel | Galvanized Steel | Good anti-corrosion and weather resistance, with a galvanized layer on the surface | Architecture, automotive components, electrical appliances |

| Copper and copper alloys | Pure copper | High electrical conductivity, good thermal conductivity, and excellent processability | Electrical equipment, wires, electronic components, furniture parts |

| Brass | Good conductivity, corrosion resistance, easy to process | Musicians, water pipes, decorations, mechanical parts | |

| Alloy steel | Alloy Steel | High strength, high hardness, strong wear resistance | Bearings, gears, automotive parts |

| Silicon steel | Silicon Steel | Good electromagnetic properties, high magnetic permeability, and reduced iron loss | Electric motors, transformers, and power generation equipment |

| Titanium alloy | Titanium Alloy | High strength, corrosion resistance, light weight, good biocompatibility | Aerospace, medical implants, ocean engineering |

| Magnesium alloy | Magnesium Alloy | Lightweight, high-strength, good rigidity, and excellent corrosion resistance | Aerospace, automotive components, electronic product casings |

| Carbon fiber composite material | Carbon Fiber Composite | High strength, lightweight, excellent rigidity, and wear resistance | Aerospace, automotive parts, sports equipment, ship parts |

| Surface treatment methods | Specific method name | Main features |

|---|---|---|

| Sanding (sanding) | Hand Sanding | Use sandpaper or sandpaper cloth to manually grind off uneven or rough surfaces |

| Mechanical Sanding | Utilize mechanical equipment for efficient surface sanding to improve consistency | |

| Polishing | Mechanical Polishing | Use polishing machinery and abrasives to polish the surface and increase glossiness |

| Chemical Polishing | Use chemical solutions to remove surface roughness and obtain a smooth surface | |

| Sandblasting | Sandblasting Rust Removal | Use high-pressure sandblasting to remove surface oxide layer and rust |

| Glass Bead Blasting | Use glass bead sandblasting agent to achieve a uniform and bright surface | |

| Heat Treatment | Flame Hardening | By heating with a flame and then rapidly cooling, the hardness of the metal is increased |

| Quenching | Improve the hardness and strength of metals through rapid cooling | |

| Tempering | Reduce quenching effect and improve toughness through heating and cooling | |

| Anti corrosion coating | Painting | Apply paint or coating onto the surface using a spray gun or brush to enhance aesthetics and prevent corrosion |

| Galvanizing | Coat the metal surface with a layer of zinc to prevent metal corrosion | |

| Rust proof oil | Cover the surface with special grease or paint to prevent corrosion | |

| Powder Coating | Powder Coating | Spray the powder onto the surface, then heat and melt to form a strong coating |

| Electroplating | Chrome Plating | Coat the metal surface with a layer of chromium to improve its appearance and corrosion resistance |

| Nickel Plating | Coat the metal surface with a layer of nickel to improve hardness and wear resistance | |

| Copper Plating | Plating a layer of copper on the metal surface to improve conductivity and decorative properties | |

| Gold Plating | Coat the metal surface with a layer of gold to enhance its appearance and decorative appeal |

Professional engineer quotation, providing you with a unique customized experience