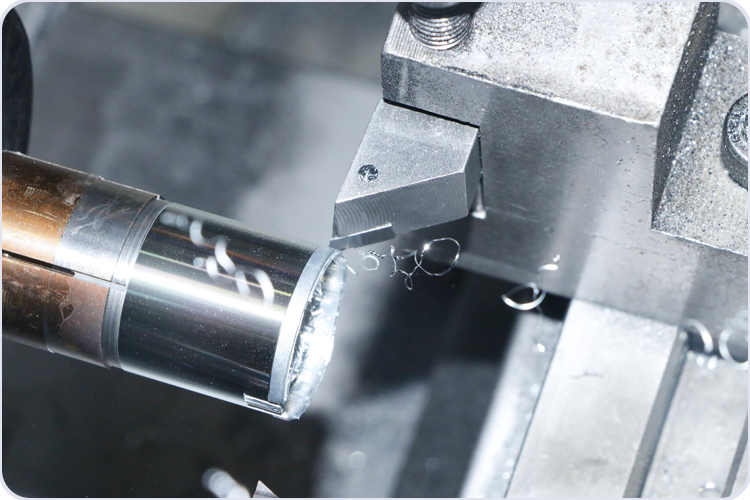

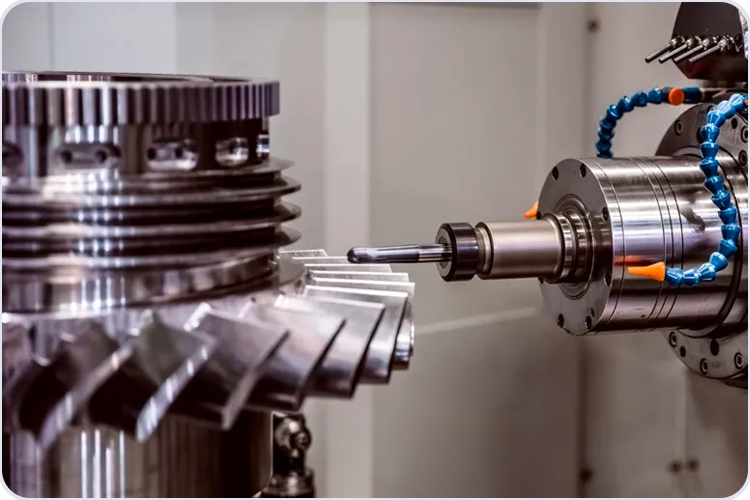

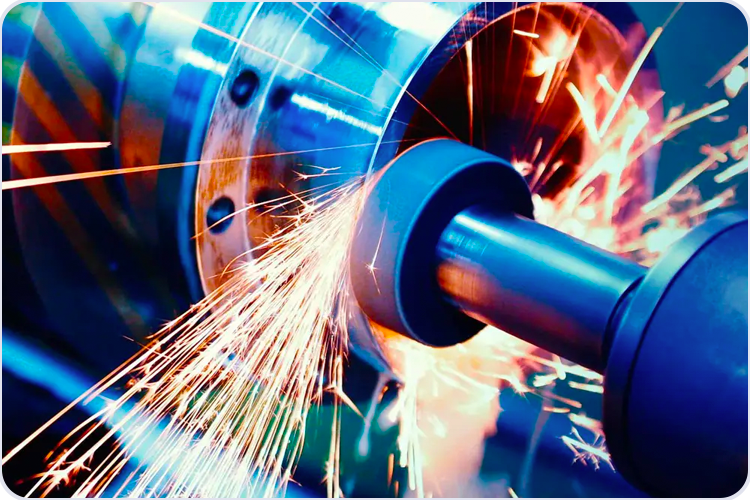

Provide various complex machining services to help you quickly sample and mass produce

| Material classification | Specific material name | Main characteristics | applications |

|---|---|---|---|

| metal | Aluminum alloy | Lightweight, moderate strength, good thermal conductivity | Aerospace, automotive, electronic components |

| Stainless Steel | Corrosion resistance, high strength, and high temperature resistance | Automotive parts, medical devices, industrial parts | |

| Brass | Good conductivity, corrosion resistance, and easy processing | Music devices, electrical connectors, decorations | |

| Steel | High strength, suitable for multiple types, and capable of passivation treatment | Structural parts, industrial equipment, automotive parts | |

| Titanium alloy | High strength, lightweight, high temperature resistance, good biocompatibility | Aerospace, medical implants, automotive parts | |

| plastics | Polypropylene | Lightweight, rigid, and resistant to chemical corrosion | Packaging, parts, household items |

| Polyethylene | Chemical corrosion resistance, wear resistance, and low temperature resistance | Container, pipeline, cable insulation | |

| Polyvinyl chloride (PVC) | Corrosion resistance, good electrical insulation, and high processability | Pipes, wire conduits, decorative materials | |

| Polystyrene (PS) | Lightweight, moderate hardness, and good insulation | Packaging, household items, model making | |

| Polyethylene terephthalate (PETG) | Impact resistant, transparent, easy to process | Parts, containers, electronic casings | |

| composite material | Carbon Fiber Composite | High strength, lightweight, corrosion-resistant | Aerospace, sports equipment, automotive parts |

| Glass Fiber Composite | Good strength and stiffness, wear resistance | Aerospace, shipbuilding, automotive parts | |

| Polymer Composite Materials | High strength, lightweight, wear-resistant | Aerospace, automotive, sports equipment | |

| Surface treatment methods | Specific method name | Main features |

|---|---|---|

| Sanding (sanding) | Hand Sanding | Use sandpaper or sandpaper cloth to manually grind off uneven or rough surfaces |

| Mechanical Sanding | Utilize mechanical equipment for efficient surface sanding to improve consistency | |

| Polishing | Mechanical Polishing | Use polishing machinery and abrasives to polish the surface and increase glossiness |

| Chemical Polishing | Use chemical solutions to remove surface roughness and obtain a smooth surface | |

| Sandblasting | Sandblasting Rust Removal | Use high-pressure sandblasting to remove surface oxide layer and rust |

| Glass Bead Blasting | Use glass bead sandblasting agent to achieve a uniform and bright surface | |

| Electroplating | Chrome Plating | Coat the surface with a layer of chromium to improve corrosion resistance and appearance |

| Nickel Plating | Coat the surface with a layer of nickel to enhance hardness and wear resistance | |

| Gold Plating | Coat with a layer of metal to provide a beautiful golden appearance | |

| Painting | Spray Painting | Spray paint with a spray gun to provide uniform color and protection |

| Powder Coating | Use static electricity to spray powder onto the surface, forming a strong coating | |

| Heat Treatment | Quenching | Improve the hardness and strength of metals through rapid cooling |

| Tempering | Reduce quenching effect and improve toughness through heating and cooling | |

| Normalization (Annealing) | Heating and slow cooling to improve the workability of metals | |

| Anti corrosion coating | Anti Rust Coating | Coating with anti-corrosion agents to improve the corrosion resistance of materials |

| Anti Scratch Coating | Anti scratch coating provides protection and improves appearance |

Professional engineer quotation, providing you with a unique customized experience